Product Advantages

|

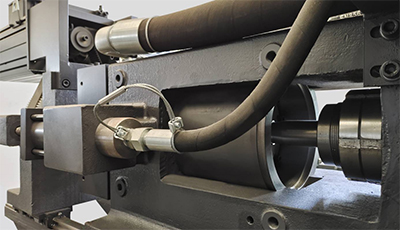

1.Single-Cylinder Injection

Utilizes a self-developed single-cylinder injection mechanism (patented), addressing oil leakage issues common in the market, while improving injection accuracy and synchronization.

|

|

|

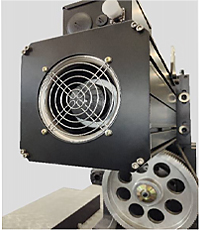

2. Electric Plasticizing

Employs a servo motor for plasticizing, offering energy efficiency, enabling compound actions, shortening the molding cycle, and delivering more significant energy savings.

|

|

|

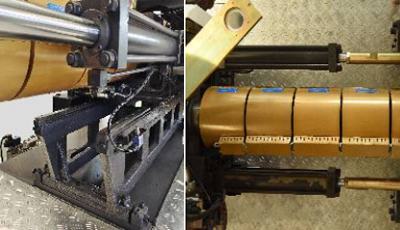

3. Nano Heating Bands

Features rapid heating, excellent heat retention, and greater energy efficiency.

|

|

|

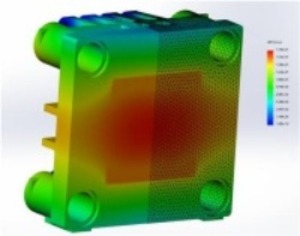

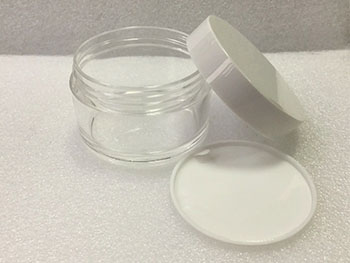

4. Fully Integrated High-Speed Machine Platens

Designed with finite element analysis, deformation coefficient is reduced by over 20%, and stress is decreased by approximately 30%, making it particularly suitable for thin-walled products.

|

|

|

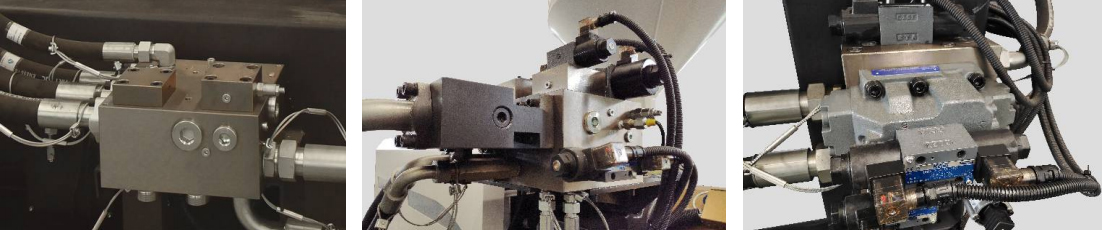

5. Hydraulic System

Specialized hydraulic circuit design for high-speed machines ensures smoother and faster mold opening and closing.

|

|

|

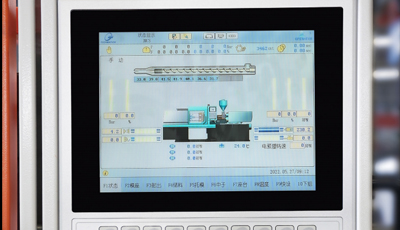

6. Controller and Electrical Components

Equipped with a high-speed machine dedicated controller from Hongxun, offering faster response times and more precise control.

Utilizes internationally renowned electrical components for stable and reliable performance. |

|

English

English  Français

Français

)97gj21(xr2ql.jpg)

+86-400-8120-669

+86-400-8120-669  sales@ouyilai.com

sales@ouyilai.com

No. 288 Lingxu Road, Cixi Coastal Economic Development Zone, Ningbo, Zhejiang, China

No. 288 Lingxu Road, Cixi Coastal Economic Development Zone, Ningbo, Zhejiang, China