Product Advantages

|

1. Wider Platen Design for Higher Efficiency and Lower Investment Cost

The tie-bar spacing of the machine is one size larger than conventional standard machines, providing greater mold capacity. For instance, a product that typically requires a 168-ton conventional injection molding machine can be produced using Shouli’s F9 Supersonic Series 140-ton model.

|

|

|

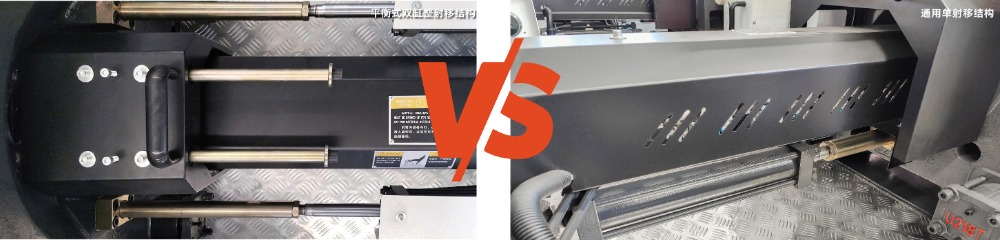

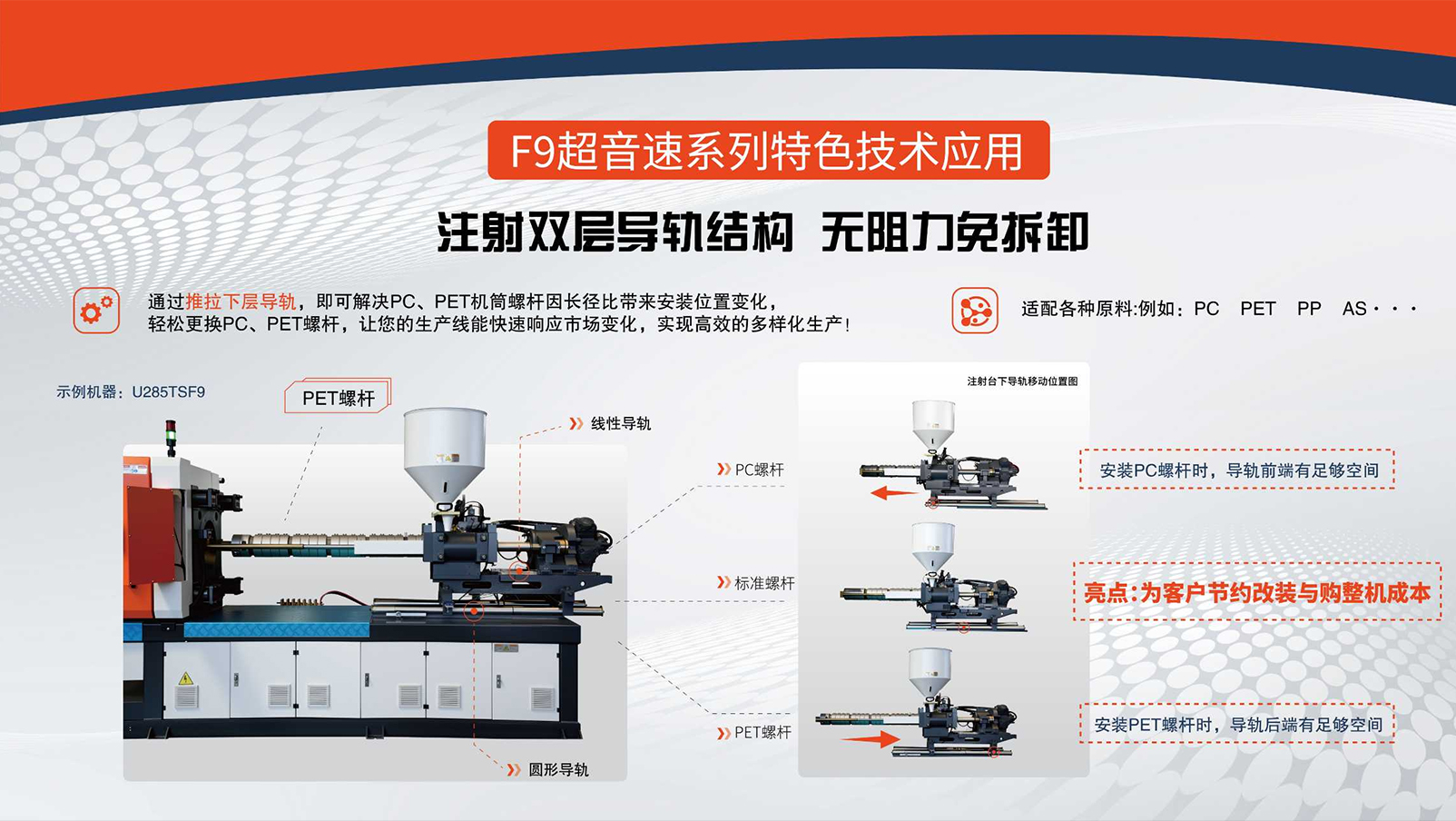

2. Double-Layer Guide Rail Injection Structure, Maintenance-Free and Easy to Adjust

The structure adopts dual-layer guide rails: the upper linear guide rail offers enhanced rigidity, ensuring smooth and precise injection without friction, improving repeatability to within 0.5%. The injection speed is increased by 10%–40%, with low noise output. The lower guide rail, designed as a standard-length component, can be moved forward or backward without disassembly, allowing easy on-site adjustment of barrel and screw lengths. Compatible with screws of various length-to-diameter ratios (e.g., for PC, PET), the machine supports multiple applications without modification.

|

|

|

3. Balanced Dual-Cylinder Injection Unit Structure for Precision, Stability, and Leak Prevention

The balanced layout of dual injection cylinders ensures precise nozzle alignment. The dual injection unit design provides stable and balanced force to maintain contact with the mold gate, enhancing injection stability and sealing to effectively prevent leakage.

|

|

|

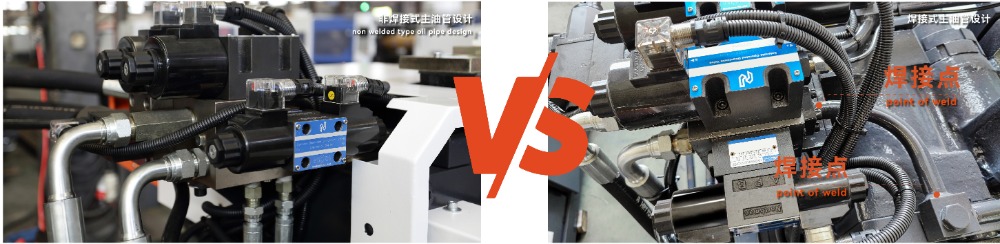

4. Non-Welded Main Oil Pipe Design for Leak Prevention and Clean Operation

Non-welded pipelines eliminate the risk of weld seam cracking and oil leakage during long-term use, reducing oil contamination. Optional high-precision bypass filtration and self-sealing suction filters, combined with non-welded pipelines and integrated cylinder assemblies, enhance oil cleanliness. The new oil circuit design offers an attractive appearance and ensures fast, stable operation, reducing costs and improving efficiency.

|

|

|

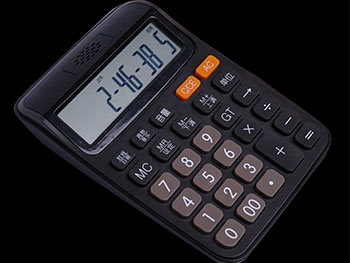

5. Dedicated Computer Controller for Efficiency, Durability, and Extensibility

Equipped with an advanced dedicated injection molding machine computer controller (Hongxun series), featuring a one-touch 12-inch aluminum-milled operation panel with a large, intuitive display. The system is durable, high-performing, and aesthetically pleasing. With secondary development capabilities, cycle scanning is significantly accelerated, sufficient I/O points are reserved, and an open programming platform supports optional high-end multi-touch screens. Compatible with multiple data interface protocols, the system offers cloud services for remote assistance and maintenance (optional).

|

|

|

6. New-Generation Servo System for Enhanced Efficiency

Ultra-fast response time achieves maximum pressure in 27ms. Compared to conventional machines of the same model/specification, molding cycles are approximately 3 seconds faster, effectively shortening production time and improving efficiency. Especially suitable for transparent product manufacturing, the high system pressure expands the range of producible items.

|

|

English

English  Français

Français

)97gj21(xr2ql.jpg)

+86-400-8120-669

+86-400-8120-669  sales@ouyilai.com

sales@ouyilai.com

No. 288 Lingxu Road, Cixi Coastal Economic Development Zone, Ningbo, Zhejiang, China

No. 288 Lingxu Road, Cixi Coastal Economic Development Zone, Ningbo, Zhejiang, China